Optimizing processes, optimizing people

For the inbound process, a warehouse manager might want to experiment with new operating methods, tweak existing steps, design a new floor layout, or completely change the handling process for inbound products until it is fully optimized and efficient. Simulation tools offer a multitude of design and modeling approaches to support managers in these design challenges.

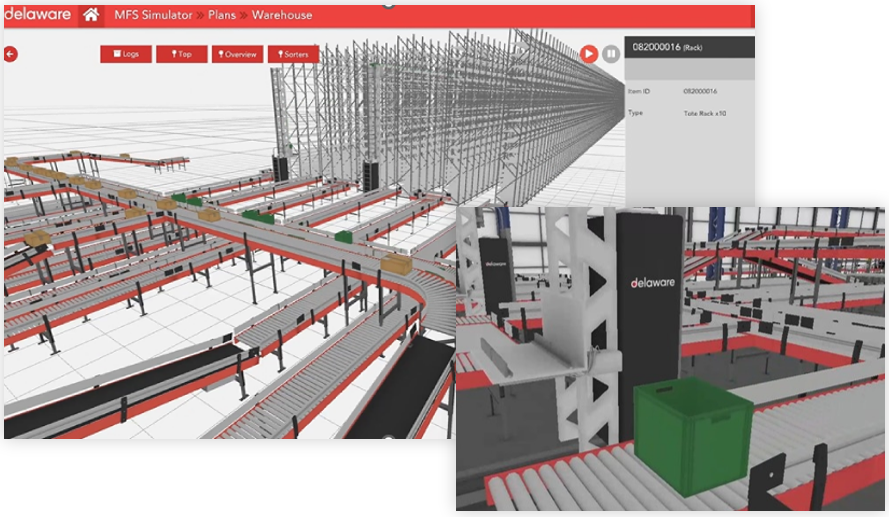

All direct labor involved in the receiving, storing, packing and shipping activities can be supported by these new 3D virtual modeling and simulation tools, including various types of equipment such as AGVs and conveyors. For example, a complete end-to-end inbound process flow can be designed within the 3D Digital Twin. It can fully simulate warehouse operators unloading bulk boxes from containers, using conveyors to move goods from the receipt zone to a palletizer machine, and finally, autonomous forklifts performing the final put-away. By using an appropriate data set, the warehouse manager can measure the current processing time for unloading goods and accurately reallocate resources based on idle time and distance coverage.

Regarding indirect labor and supervision, the new digital platform offers a plethora of dashboards to model and measure current performance and provide options to further model and measure potential increases in process efficiency. Additionally, trainers can use the 3D virtual digital warehouse to visualize and upskill warehouse leaders and team operators with respect to any new future layouts and procedures.

For the outbound process, retailers are continually looking for the optimal picking process. By using the 3D virtual digital warehouse, they can optimize the picking process using carts with the correct number of trays required to fulfill e-commerce orders. Another major challenge that can be digitally modeled is optimizing the exit capacity of the total sorting and packing work center availability. All these operational process design challenges can be represented in a 3D Digital Twin simulation tool to allow upfront design and analysis, providing a clear view of how to fine-tune operational parameters for better, more optimized results, ultimately reducing upfront capital and long-term operational costs.

/ABB-Robotics-(2).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=187f919b-df44-40ed-94ac-4aa886c0b64e&v=&c=11d4c4659b1db0f3b7d768216a0ef4725bce8fbaf4a900d3aae78d128745483a)

/discrete_manufacturing-banner-3200x500-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=629d418c-dbf5-4118-a5e9-b73f30493781&v=&focusX=2165&focusY=266&c=63571864ad8e6ac620a19cb48f79c025904b15d83863cda6c5c0cb16f7819dcf)

/smart_warehouse_logistics-banner-3200x500-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=cacbc109-51a2-4d30-9dde-3a24a8dcc9f6&v=&focusX=2062&focusY=248&c=ed059bbb543a0293e280c2627e564ea5f472ff30f9d6df083c91827e66e6b233)